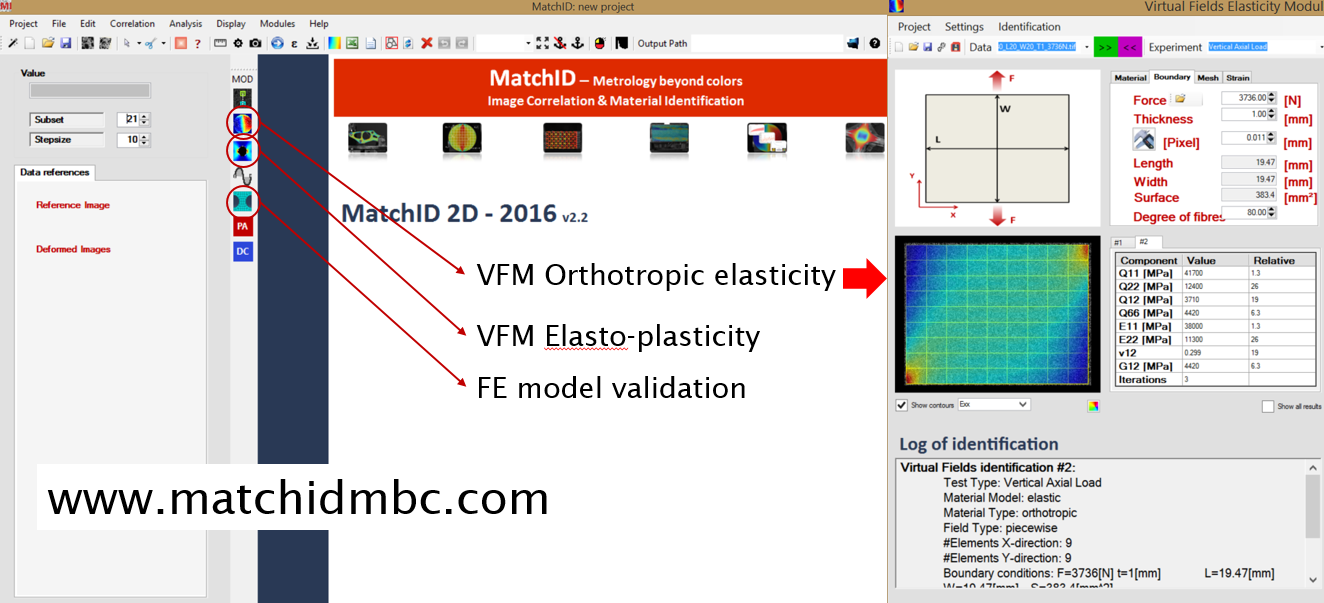

Digital Image Correlation is a widespread technique that relies on imaging the deformation of a random pattern affixed at the surface of the test specimen. The technique tracks displacements of subsets of pixels between the reference and deformed configurations. The Photodyn group uses the MatchID DIC platform which integrates VFM identification as well as other features like synthetic image deformation from finite element displacement maps to realistically simulate measurements. DIC is well adapted to large strains and lower strain gradients whereas the grid method is generally better for small strains and higher strain gradients.

Example of a speckle pattern

MatchID commercial DIC/VFM software platform

Speckle pattern printing

Here are instructions to print a speckle pattern directly on specimens using a Canon Océ Arizona 1260 XT printer. It is a UV flatbed inkjet technology printer, and can print on surfaces as large as 2.51m (98.8″) x 3.09m (121.6″) on rigid substrates up to 50.8 mm (2.0″) thick. The printer uses vacuum to secure media to the printer table.

Instructions for printing the DIC pattern

The following speckle patterns can be used.

- This pattern is from Bossuyt, S. (2013). Optimized patterns for digital image correlation. Proceedings of the Society for Experimental Mechanics Series. Speckle pattern 1

- This one is from Dr Richard Burguete, NPL, UK (formerly at Airbus UK, Filton). Speckle pattern 2

Some resources

- Sutton, M. A., Orteu, J. J., & Schreier, H. W. (2009). Image Correlation for Shape, Motion and Deformation Measurements: Basic Concepts, Theory and Applications. Image Correlation for Shape, Motion and Deformation Measurements: Basic Concepts, Theory and Applications, 1-321. doi:Doi 10.1007/978-0-387-78747-3

- DIC Challenge

- DIC training course