The Photodyn project proposes an alternative to the well-known Split Hopkinson Pressure Bar (SHPB) apparatus to identify the high strain rate behaviour of materials. The idea is to perform inertial impact tests using a gas gun system attached to an impact chamber where imaging of the specimen response will be performed using an ultra-high speed camera.

The gas gun has been designed to be capable of impact speeds up to 100 m/s for an aluminium projectile of mass 0.44 kg (impact energy of 2.2 kJ). The barrel of the gas gun is 3 m long and has a 50 mm bore. The pressure reservoir uses compressed air as a working fluid, has a volume of 12 L and a maximum working pressure of 20 bar. The firing valve is a solenoid valve with a 2″ port and a max opening time of 200 ms. The test section has optical access on both sides and is capable of mounting specimens up to 220 x 220 x 220 mm.

Principle of the gas gun

Click on the image for an animation of the principle of the gas gun

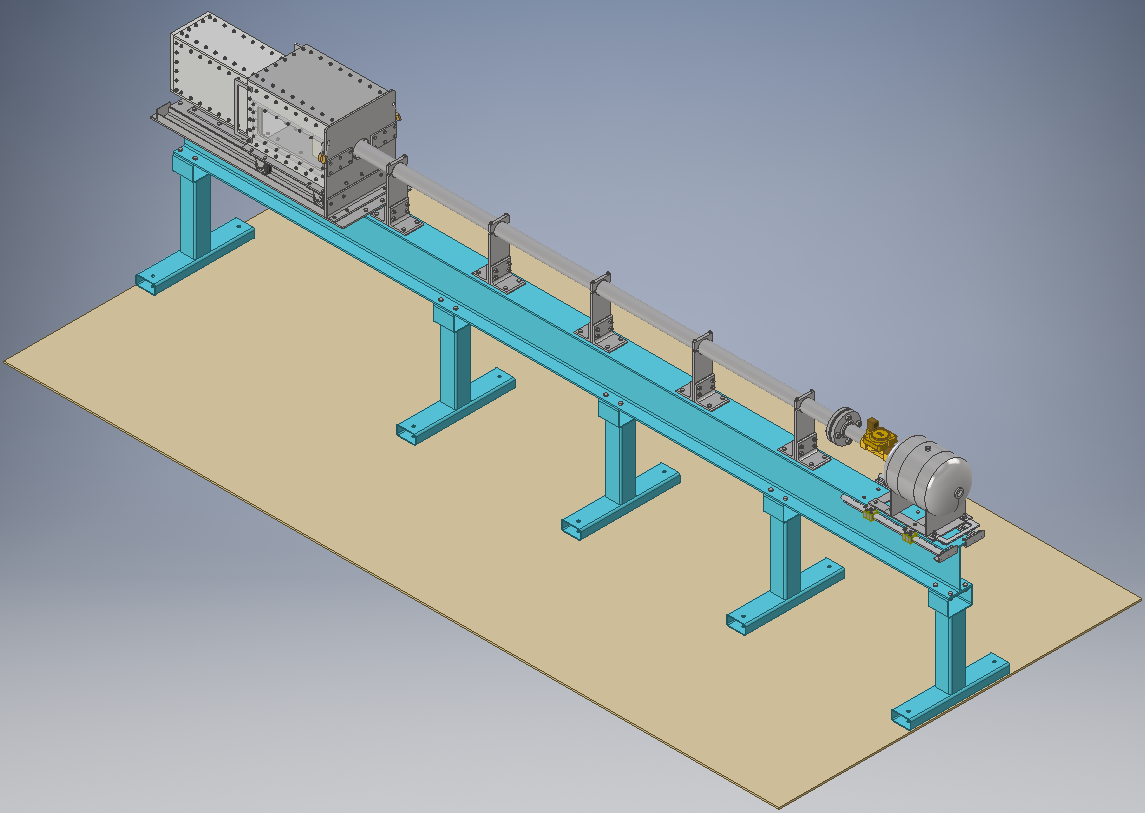

Full CAD assembly model of PhotoDyn impact rig

Full design specification and CAD drawings for the gas gun can be provided on request.